Capabilities

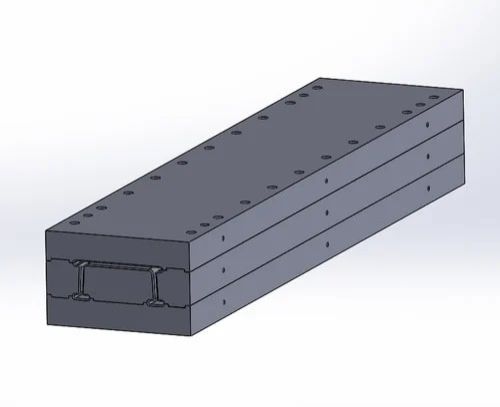

Custom Pultrusion Dies Built to Perform

We design and manufacture pultrusion dies for standard and complex profiles—from window lineals and ladder rails to tubes, rods, and flat strips. Our process blends advanced engineering with decades of hands-on experience to deliver precision tools that are built to global standards and delivered at smart costs.

Core Capabilities

Precision Machining

- CNC machining centers

- EDM (Electrical Discharge Machining)

- Gundrilling

- Grinding (up to 60")

- Large-die handling & surface finishing

In-House Engineering

- Advanced CAD modeling and simulation

- Tight-tolerance cavity sizing based on shrinkage calculations

- Collaborative design approach to ensure manufacturability and product quality

Design Excellence

- Smart section sizing for optimal cost-performance balance

- Seamless and parting-surface die options

- Material selection tailored for longevity, compatibility, and performance

Customer-Centric Advantages

- Designs accepted in all formats via CAD/CAM

- Joint development by mold engineers & process specialists

- Fast quote, custom design, and delivery turnaround